30+ Years Plastic Injection Molding Manufacturing Service

Custom plastic injection molding with AIM plastic, with design and engineering support, OEM, ODM, injection mold making, competitive price, shipment support etc

One-stop Injection Molding Solutions

AIM Plastic specializes in comprehensive, one-stop injection molding solutions, leveraging advanced precision technology and flexible production capabilities. With over 30 years of industry experience, we consistently deliver high-quality, reliable plastic components to customers worldwide. Our proactive engineering support, rigorous quality control, and efficient production workflow allow us to transform complex concepts into fully finished parts. To date, AIM Plastic has manufactured thousands of customized components across industries including packaging, automotive, industrial, and consumer goods.

How to Work with Us

Got an injection molding design ready? Bringing it to life has never been simpler. Simply upload your CAD file to receive a tailored quote, expert design recommendations, engineering support, low minimum order quantities, shipping assistance, and more—making the transition to mass production effortless. We guarantee every part is delivered on time and meets the highest quality standards.

Upload your 3D files

To start your project, pls provide your 3D files in .stp format for our checking

Get a quote form us

You will get our price quotation within few hours

Bulk manufacturing

Once confirmed, we will proceed bulk production and arrnage finishing operation, assembly etc if needed.

Products shipment

Your products are shipped securely worldwide, and we can offer shipment support if your request

Our Factory Capacities

Our capabilities cover precision engineering, mold design and tooling fabrication, injection molding, CNC machining, assembly, and post-finishing services. Supported by advanced equipment and skilled technicians, we efficiently handle projects from low-volume production to full-scale manufacturing, delivering consistent quality and fast turnaround

Design and engineering support

- Material Selection Guide

- Injection Mold Design Support

- Injection molding Process Optimization

- Prototype injection molding

- Bulk Manufacturing Optimization

- Post-finishing Service

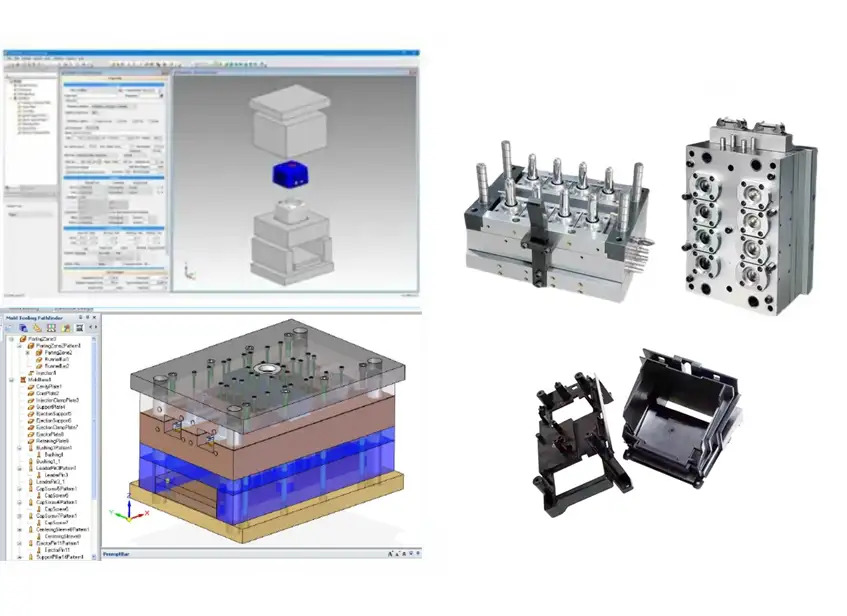

Custom injection mold

- Precision Engineering support

- Advanced Manufacturing Equipment

- Fast mold opening

- Durable mold tooling materials

- Experienced Technical Team

- Reliable Quality Control

- Cost-Effective Solutions

Our injection molding capacities

- Advanced Injection Molding Machinery

- Strict Quality Assurance

- Efficient Production Workflow Optimization

- Flexible OEM and ODM Service

- Precision Manufacturing in bulk production

- Post-finishing and assembly support

Custom your injection molded parts

If you have customized plastic inejcton molded parts, pls send us an inquiry, we will provide professional solution for your project within few hours

FAQ For Custom Injection Molding

Injection molding is a manufacturing process that produces plastic parts by injecting molten material into a precisely engineered custom mold. Once the plastic cools and solidifies, the mold opens and the finished part is ejected, ensuring high accuracy and consistent quality from part to part.

FAQs about injection molding usually address practical concerns such as tooling and mold costs, minimum order quantities, material selection, cycle times, and achievable tolerances. They also explain how design factors—like wall thickness, draft angles, ribs, and material choice—directly influence manufacturability, product strength, surface finish, lead time, and overall production cost.

Our injection molding capacities

Do not get your answer yet? No worry, let us, AIMP Plastic help your plastic injection molding issues!

What is custom injection molding?

Custom injection molding is a manufacturing process where plastic parts are produced using a mold designed specifically for a customer’s product requirements, dimensions, and performance needs.

What materials can be used in custom injection molding?

Common materials include ABS, PP, PE, HDPE, nylon, PC, TPU, POM, and PMMA. Material choice depends on strength, flexibility, temperature resistance, and application environment.

How much does a custom injection mold cost?

Mold costs vary based on part complexity, size, cavities, and material, typically ranging from a few thousand to tens of thousands of dollars.

What is the minimum order quantity (MOQ)?

MOQs depend on the supplier and tooling setup. Some manufacturers support low-volume production, while others focus on high-volume runs.

How long does it take to make a custom injection mold?

Mold fabrication usually takes 3–8 weeks, depending on complexity, tooling material, and design revisions.

What tolerances can custom injection molding achieve?

Injection molding can achieve tight tolerances, often within ±0.05 mm, depending on material and part geometry.

How does part design affect injection molding cost?

Design factors such as wall thickness, undercuts, draft angles, and part size directly affect mold complexity, cycle time, and overall cost.

Can injection molding handle complex geometries?

Yes, injection molding is ideal for producing complex shapes, intricate details, and high-precision features with excellent repeatability.

What is the typical production cycle time?

Cycle times usually range from a few seconds to several minutes, depending on material type, part thickness, and cooling requirements.

Is custom injection molding suitable for prototyping?

Yes, it can be used for functional prototypes, especially when production-grade materials and accurate dimensions are required.

How durable are injection-molded parts?

Durability depends on material selection and design. Properly engineered parts offer high strength, impact resistance, and long service life.

Can surface finishes or textures be customized?

Yes, molds can include polished, matte, textured, or patterned finishes, and parts can also undergo post-processing treatments.

What industries commonly use custom injection molding?

Automotive, medical, electronics, packaging, consumer products, industrial equipment, and construction industries widely use custom injection molding.

How do design changes impact production?

Minor design changes may only affect tooling inserts, while major changes can require mold modifications or a new mold, impacting cost and lead time.

How do I get started with a custom injection molding project?

You typically start by submitting a CAD file, discussing material and application requirements, receiving DFM feedback, and reviewing a customized quote before tooling begins.

Get a quote for your project

Get a quote for your custom injection molding project today and discover a reliable solution for producing high-quality, multi-material components. Our experienced team supports custom design, material selection, DFM, mold flow analysis to ensure strength, precision, and cost-effective manufacturing for injection mold projects.

AIM Plastic, Your Plastic Injection Molding Manufacturing Partner

In today’s fast-moving manufacturing landscape, choosing the right plastic injection molding partner is no longer just about price. It’s about reliability, engineering capability, quality control, scalability, and long-term collaboration within a proven plastic injection molding manufacturing environment. This is where AIM Plastic stands out as an experienced injection molding company delivering complete molding solutions.

With more than three decades of hands-on experience in plastic injection molding, AIM Plastic has grown into a trusted plastic injection molding manufacturing partner for global customers across automotive, medical, industrial, electronics, and consumer product sectors.

From concept to mass production, AIM Plastic supports every stage of theplastic injection molding manufacturing process, from mold design and injection mold tooling to producing precision molded parts using modern injection molding machines. Every plastic part is manufactured with precision, consistency, and speed.

This article explores who AIM Plastic is, what we do, how we work across different plastic injection molding manufacturing processes, and why manufacturers worldwide choose us as their long-term custom plastic injection molding partner.

Who Is AIM Plastic?

AIM Plastic is a professional plastic injection molding manufacturer specializing in custom plastic components, molded parts, and assemblies.

With over 30 years of plastic injection molding manufacturing experience covering the basics of plastic injection molding as well as the latest injection molding technology, the company combines deep engineering knowledge with modern injection molding equipment to deliver stable, repeatable, and cost-effective molding manufacturing solutions.

From the early history of plastic injection molding and the first screw injection machine to today’s automated molding systems, AIM Plastic has evolved with the industry. The company operates under strict quality standards and holds internationally recognized certifications, including:

ISO 9001 – Quality Management System

ISO 13485 – Medical Device Manufacturing

IATF 16949 – Automotive Quality Management

These certifications reflect AIM Plastic’s commitment to controlling every injection process, from plastic resin selection and injection speed control to final inspection of parts and components after they are ejected from the halves of the mold.

Plastic Injection Molding as a Core Capability

What Is Plastic Injection Molding?

Plastic injection molding is a manufacturing method in which molten plastic, or melted plastic resin, is injected through an injection unit into a precision injection mold. Once the molten plastic fills the mold cavity, it cools, solidifies, and the finished part from the mold is ejected. This plastic injection molding process is one of the most widely used manufacturing processes for producing plastic parts at scale.

The advantages of plastic injection molding manufacturing include:

High-dimensional accuracy for precision-molded parts

Excellent repeatability across molding cycles

Complex geometries with consistent quality

Smooth and controlled surface finishes

Scalable low-volume production molding to high-volume injection molding

AIM Plastic applies modern injection molding techniques, scientific injection pressure control, and optimized injection molding cycle time to ensure each plastic molding project meets functional, aesthetic, and cost requirements.

Comprehensive Injection Molding Services at AIM Plastic

AIM Plastic is not just a plastic injection molding manufacturing supplier—it is a full-service plastic injection molding manufacturing partner covering the entire injection molding process.

Custom Mold Design and Tooling Fabrication

Every successful injection molding manufacturing project begins with a high-quality injection mold. AIM Plastic provides complete injection mold tooling services, including mold tool fabrication and injection mold design optimization.

Capabilities include:

Advanced mold design based on plastic part design guidelines

DFM and mold flow analysis to predict the filling behavior of molten plastic

Multi-cavity, family mold, and micro injection molding solutions

Steel, aluminum, and rapid prototyping injection molding tools, including 3D printed injection molds

High-precision CNC machining, EDM, and mold maintenance

By optimizing gate and runner design, cooling system optimization, and injection pressure control, AIM Plastic minimizes common plastic injection molding manufacturing defects such as warpage, sink marks, air traps, and short shots during the first injection and subsequent injection cycles.

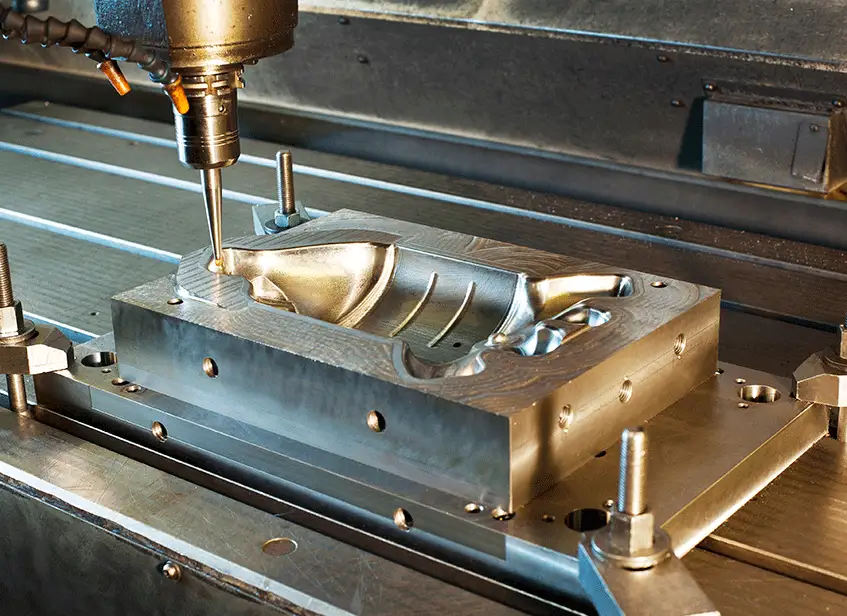

Plastic Injection Molding Production

AIM Plastic supports low-volume, mid-volume, and high-volume injection molding production using modern plastic injection molding machines with stable process control.

Production capabilities include:

A wide range of injection molding machine tonnage

Automated molding systems for consistency

Scientific molding techniques based on injection speed and injection pressure

Real-time monitoring of the injection unit and plastic injection molding manufacturing processes

Stable cycle times and high yield rates across molding manufacturing

From pilot runs to full-scale molding manufacturing, AIM Plastic ensures consistent production of plastic molded parts across different injection molding applications.

Material Selection and Engineering Support

Plastic resin selection plays a critical role in determining part performance, durability, and cost. AIM Plastic offers engineering support to match injection molding materials with application requirements.

Common injection molding materials include:

ABS

PP

PE / HDPE

Nylon (PA6, PA66)

Polycarbonate (PC)

TPU

POM (Acetal)

PMMA

Whether the application requires thermoplastic injection molding, thermoset injection molding, gas-assisted injection molding, or two-shot injection molding, AIM Plastic ensures the selected plastic resin meets mechanical, thermal, and chemical performance standards.

Secondary Operations and Assembly

To reduce supply chain complexity, AIM Plastic provides integrated secondary operations alongside plastic injection molding manufacturing processes.

Services include:

CNC machining

Ultrasonic welding

Insert molding and overmolding techniques

Gas-assisted injection for thick-wall parts

Pad printing and silk screening

Surface finishing

Product assembly and packaging

This integrated molding solution allows customers to receive ready-to-use parts and components without managing multiple suppliers.

Industries Served by AIM Plastic

Automotive Injection Molding

AIM Plastic supports automotive plastic injection molding manufacturing applications with components that meet strict durability, safety, and performance standards.

Typical automotive molded parts include:

Interior trim components

Clips, brackets, and housings

Under-the-hood plastic parts

Structural and functional plastic components

Compliance with IATF 16949 ensures every injection molding manufacturing process follows automotive-grade quality requirements.

Medical Plastic Injection Molding

Medical injection molding requires strict control of materials, molding techniques, and manufacturing processes. AIM Plastic’s ISO 13485-certified systems support:

Medical device housings

Diagnostic equipment components

Wearable medical parts

Disposable medical plastic components

Controlled environments, traceable injection molding materials, and validated injection molding techniques ensure regulatory compliance.

Electronics and Electrical Components

For electronics injection molding applications, AIM Plastic produces:

Enclosures and housings

Connectors and insulation components

Precision structural plastic parts

Tight tolerances, controlled injection pressure, and consistent molding technology ensure reliable performance across electronic products.

Industrial and Consumer Products

AIM Plastic also serves industrial and consumer markets with versatile molding solutions, including:

Tools and equipment parts

Household product components

Packaging-related plastic parts

Custom OEM plastic injection molding manufacturing solutions

From the first injection molding design to final mass production, AIM Plastic applies the latest injection molding technology to produce high-quality plastic parts that balance durability, cost efficiency, and appearance.

Quality Control: Built Into Every Step

Quality at AIM Plastic is not an afterthought—it is embedded into every process involved in manufacturing plastic parts. From plastic material selection to the final production of parts, manufacturing quality control is applied across tooling, molding, finishing, and delivery.

This ensures every plastic component meets defined plastic molding tolerances, whether producing small parts, complex plastic structures, or high-volume automotive parts.

Injection molding is a manufacturing process that is highly automated, and AIM Plastic designs quality into the system by controlling mold cavity conditions, cycle time stability, clamping and injection units, and process and material consistency within the mold.

Advanced Quality Systems

AIM Plastic implements robust quality assurance in molding through advanced inspection and monitoring systems integrated into polymer processing technologies.

AIM Plastic implements:

Incoming plastic material inspection to verify suitability for injection

In-process quality checks during plastic injection molding

First article inspection (FAI) to validate mold cavity performance

Dimensional measurement and testing for precision injection molded assemblies

Final inspection before shipment to ensure high-quality plastic products

Statistical process control (SPC) is applied throughout the injection molding process, allowing manufacturers to detect excessive injection pressure, flash and warpage risks, and cycle time variation early—before defects impact production volume.

Traceability and Documentation

For regulated industries and high-reliability applications, AIM Plastic provides full traceability and documentation across the injection molding tooling components and manufacturing lifecycle.

This includes:

Material certificates covering thermoplastic and thermoset materials

Process records documenting injection ram behavior and molten plastic flows

Inspection reports verifying parts are created within the specification

Batch traceability linking finished plastic products back to mold inserts and process settings

This level of documentation ensures transparency, accountability, and confidence in high-volume and precision manufacturing environments.

Cost Efficiency Without Compromising Quality

One of the biggest advantages of partnering with AIM Plastic is cost optimization through engineering, not shortcuts. Injection molding allows efficient manufacturing of a large number of parts using a preferred manufacturing method proven across industries.

Cost-saving strategies include:

Design optimization to improve mold cavity filling and reduce excessive injection

Multi-cavity mold production to increase output without extending cycle time

Plastic material selection balancing performance, durability, and cost

Automation and industrial molding equipment to reduce labor dependency

Stable processes that minimize scrap rates and support sustainable plastic manufacturing

Injection molding cost analysis is conducted early to ensure cost efficiency without compromising part integrity or quality.

Flexible MOQs and Scalable Production

Unlike manufacturers focused only on high volume, AIM Plastic supports flexible production models across the full lifecycle of plastic injection molding manufacturing.

This includes:

Low-volume production for startups and validation of extremely small parts

Medium-volume manufacturing for growing brands producing plastic products

High-volume mass production is suitable for injection molding applications requiring consistency and speed

Because the process is highly automated and scalable, customers can smoothly increase the number of parts produced as demand grows.

Engineering Collaboration: More Than a Supplier

AIM Plastic positions itself as a manufacturing partner, not just a supplier of plastic components.

From the earliest design stage, AIM Plastic engineers collaborate closely with customers to utilize plastic injection molding efficiently and intelligently. This includes support in tool and die engineering, mold insert fabrication, screw and barrel design optimization, and flash and warpage reduction.

Collaboration focuses on:

Improving manufacturability and reducing mold maintenance needs

Optimizing part performance within the mold

Reducing tooling risks, mold maintenance, and repair costs

Shortening time to market through proven molding technology

Customers learn more about injection molding as a process and material system, enabling better design decisions and long-term product success.

Why Choose AIM Plastic as Your Injection Molding Partner?

Manufacturers worldwide choose AIM Plastic as their injection molding company for several proven reasons:

30+ years of expertise across the history of plastic injection molding

ISO certified molding services (ISO 9001, ISO 13485, IATF 16949)

Strong engineering capabilities covering CNC-machined molds and tooling

Stable, scalable production capacity for manufacturing plastic parts

Competitive pricing supported by injection molding cost analysis

One-stop manufacturing, including finishing and secondary operations

Responsive communication and long-term project support

Injection molding provides the ability to produce complex plastic parts reliably, and AIM Plastic ensures this capability is delivered consistently.

From Concept to Production: How AIM Plastic Works

Project Evaluation – Review CAD files, application requirements, plastic material suitability, and performance goals

DFM & Engineering Feedback – Optimize design for molding efficiency, mold cavity balance, and durability

Quotation & Timeline – Transparent pricing, cycle time estimation, and clear production schedules

Tooling Development – CNC-machined molds, injection molding tooling components, and testing

Sample Approval – First articles validated for quality and performance

Mass Production – Process is highly automated, monitored, and optimized

Inspection & Delivery – Quality assurance in molding and global shipping support

This workflow reflects that injection molding is one of the first and most reliable manufacturing methods developed, dating back to when Eichengrün developed the first injection molding concepts—now evolved into modern, high-precision systems.

Long-Term Manufacturing Partnership

In an era where supply chain stability matters more than ever, AIM Plastic focuses on long-term partnerships, not one-off transactions.

Customers benefit from:

Continuous process improvement and mold maintenance

Ongoing cost optimization and plastic recycling in manufacturing

Consistent production of parts across years and platforms

Scalable capacity for products for many industries

Injection molding is one of the preferred manufacturing processes, allowing manufacturers to adapt as markets evolve. AIM Plastic grows alongside its customers.

Start Your Plastic Injection Molding Project with AIM Plastic

Plastic injection molding is one of the most widely used methods to create plastic products by forcing molten material into the mold. Plastic is injected, plastic is forced, and molten plastic flows within the mold to form precise shapes.

If you’re looking for a reliable plastic injection molding, insert molding, overmolding manufacturing partner that combines engineering expertise, ISO-certified quality, and flexible production, AIM Plastic is ready to support your project.

From prototype to high-volume manufacturing, injection molding provides unmatched efficiency. AIM Plastic delivers precision, consistency, and confidence—producing parts manufacturers trust for long-term success.